Liquid Penetrant Testing

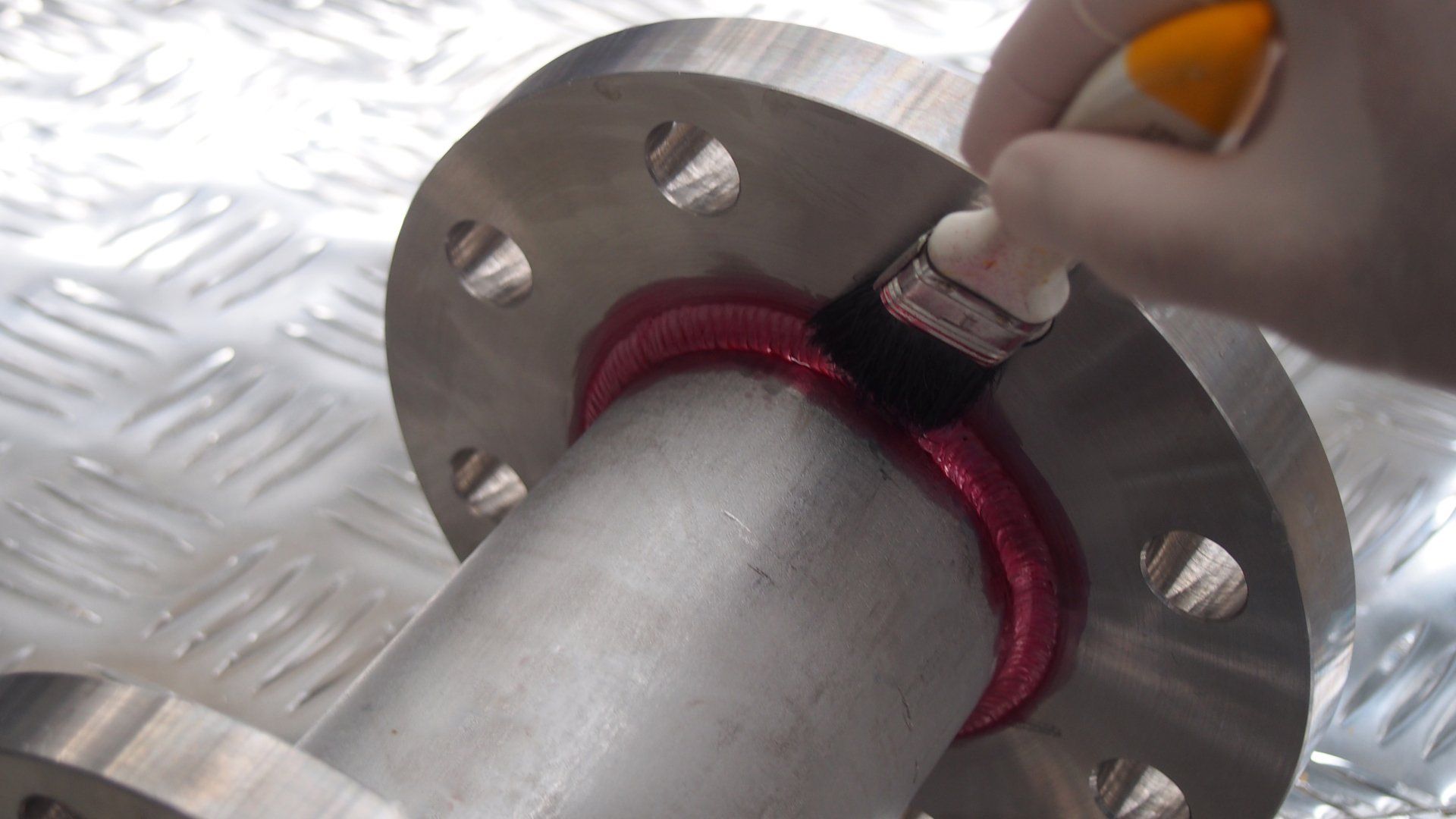

Liquid Penetrant Testing (PT) is an NDT method used to locate surface-breaking defects and/or discontinuities. A low-viscosity fluid known as a penetrant is applied to the part and allowed to dwell on the part for a specified time. The excess penetrant is carefully removed and a developer is applied which draws the penetrant out of defects and/or discontinuities through capillary action and provides a contrasting background to improve the visibility of the indications.

Materials inspected include non-ferrous and ferrous materials, although ferrous materials are typically inspected with Magnetic Particle testing for its subsurface detection capabilities. This method is used to detect casting, forging and welding surface defects and/or discontinuities such as cracks, surface porosity, leaks, fatigue cracks on in-service components, and inherent manufacturing flaws.

Surface preparation is critical and it is therefore important to ensure surfaces are free of oil, grease, scale, paint, rust or other residues that may affect the quality of inspection.